Food Safety Hand Protection: Complete Guide to Preventing Pathogen Contamination and Cross Contact

Understand hand related food safety risks

Food workers’ hands serve as the primary vehicle for pathogen transmission in commercial kitchens. Every surface touch, ingredient handle, and utensil grasp create potential contamination pathways that can compromise food safety. Understand these risks form the foundation for implement effective protective measures.

Pathogens include salmonella, e. Coli, norovirus, and staphylococcus aureus normally reside on human hands. These microorganisms multiply quickly under favorable conditions, make proper hand protection crucial for preventing foodborne illness outbreaks. The consequences of inadequate hand hygiene extend beyond individual health risks to encompass business reputation, legal liability, and regulatory compliance.

Essential hand hygiene protocols

Proper handwashing represent the virtually fundamental defense against pathogen transmission. Food workers must wash hands good use warm water and soap for at least twenty seconds, ensure coverage of all surfaces include fingertips, thumbs, and areas between fingers.

Critical handwash moments include arrival at work, after use restrooms, follow breaks, after handle raw proteins, before switch between food preparation tasks, after touch face or hair, follow equipment cleaning, and after handle waste materials. Each washing cycle must involve vigorous scrub to physically remove pathogens and organic matter.

Hand sanitizers provide supplementary protection but can not replace proper handwashing. Alcohol base sanitizers contain at least sixty percent alcohol efficaciously reduce pathogen loads when hands appear clean. Yet, sanitizers prove ineffective against certain pathogens like norovirus and lose efficacy when apply to visibly soil hands.

Strategic glove usage

Disposable gloves create physical barriers between hands and food products when use right. Food workers must understand that glove supplement instead than replace handwash protocols. Hands require washing before glove application and after glove removal to maintain safety standards.

Single use gloves demand frequent changes to prevent cross contamination. Workers must replace gloves when switch between raw and ready to eat foods, after touch non-food surfaces, follow any break in glove integrity, and at regular intervals during extend food preparation sessions. Glove washing or reuse compromise their protective function and violate food safety protocols.

Proper glove selection matter importantly. Nitrile gloves offer superior puncture resistance and chemical compatibility compare to latex alternatives. Food grade gloves must meet regulatory standards and provide adequate dexterity for specific tasks while maintain barrier protection.

Source: grammar. Cl

Prevent cross contact through systematic approaches

Cross contact occur when allergen transfer from one food to another through share surfaces, equipment, or handle practices. This invisible contamination pose serious health risks for individuals with food allergies and require comprehensive prevention strategies.

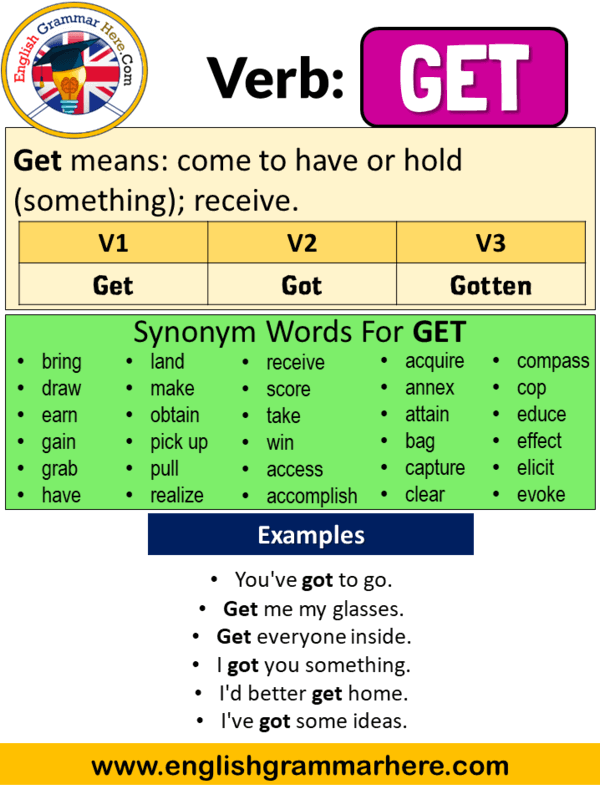

Source: englishgrammarhere.com

The virtually critical step food workers must complete to prevent cross contact involve implement dedicated preparation areas and utensils for allergen contain foods. This separation strategy eliminate opportunities for allergen transfer during food preparation processes.

Color code cutting boards, utensil, and containers provide visual cues that help workers maintain separation protocols. Red boards for raw meat, green for vegetables, blue for seafood, and yellow for poultry create systematic approaches that reduce human error. Dedicated allergen preparation areas require separate storage, clean supplies, and handle procedures.

Equipment and surface sanitization

Hand protection extend beyond personal hygiene to encompass proper equipment handling and surface sanitization. Food workers must clean and sanitize all contact surfaces before food preparation and between different food types. This process remove both visible contamination and microscopic pathogens.

Three compartment sinks facilitate proper equipment washing through sequential wash, rinse, and sanitize steps. Chemical sanitizers require specific concentrations and contact times to achieve pathogen destruction. Test strips verify sanitizer strength and ensure effectiveness throughout service periods.

Thermometers, cutting boards, knives, and preparation surfaces demand particular attention due to frequent food contact. Workers must avoid bare hand contact with sanitized equipment and allow proper air dry to maintain sanitation effectiveness.

Personal hygiene standards

Comprehensive hand protection require attention to overall personal hygiene practices. Fingernails must remain short, clean, and unpolished to prevent pathogen harboring. Artificial nails and nail jewelry create additional contamination risks and typically violate food service regulations.

Hand and arm wounds require proper covering with waterproof bandages and gloves to prevent pathogen transmission. Open cuts provide direct pathways for dangerous bacteria like staphylococcus aureus to contaminate food products. Workers with hand injuries may require task modifications or temporary reassignment.

Jewelry removal from hands and arms eliminate surfaces where pathogens accumulate. Rings, bracelets, and watch create cleaning challenges and provide hiding places for harmful microorganisms. Simple wedding bands may receive exceptions in some jurisdictions but require extra attention during handwash.

Temperature control considerations

Hand protection protocols must account for temperature sensitive food handling requirements. Cold foods demand minimal hand contact time to prevent temperature abuse. Workers should use utensils, tongs, or scoops whenever possible to reduce direct hand contact with temperature control items.

Hot food handling require protective equipment beyond standard gloves. Heat-resistant gloves or utensil prevent burns while maintain food safety standards. Workers must avoid touch ready to eat foods with bare hands disregardless of temperature to prevent pathogen transmission.

Training and compliance monitoring

Effective hand protection require comprehensive staff training and ongoing compliance monitoring. Food workers need regular education update cover proper techniques, regulatory changes, and emerge best practices. Hands-on training sessions provide opportunities to practice correct procedures and address individual challenges.

Supervision and monitoring systems ensure consistent application of hand protection protocols. Regular observations, compliance checklists, and corrective action procedures maintain safety standards throughout daily operations. Documentation of training and monitoring activities support regulatory compliance and continuous improvement efforts.

Regulatory framework and standards

Food safety regulations establish minimum requirements for hand protection in commercial food service operations. The FDA food code provide comprehensive guidance on handwash procedures, glove usage, and cross contamination prevention. Local health departments may impose additional requirements base on regional considerations.

HACCP systems incorporate hand hygiene as critical control points in food safety management. Monitor procedures, corrective actions, and verification activities ensure systematic approaches to pathogen prevention. Regular third party audits verify compliance with establish protocols and identify improvement opportunities.

Technology integration

Modern food service operations progressively incorporate technology solutions to enhance hand protection protocols. Automated handwashing stations ensure consistent water temperature and timing while reduce human variables. Electronic monitoring systems track handwash frequency and duration to support compliance efforts.

Sensor activate dispensers for soap and sanitizer reduce cross contamination risks while ensure product availability. Digital training platforms provide interactive education opportunities and track completion rates for regulatory compliance. These technological enhancements supplement traditional protocols without replace fundamental hygiene practices.

Implementation strategies

Successful hand protection programs require systematic implementation approaches tailor to specific operational needs. Assessment of current practices identify gaps and improvement opportunities. Write procedures provide clear guidance for consistent application across all staff members.

Supply management ensure adequate availability of handwash facilities, soap, sanitizer, gloves, and other protective equipment. Strategic placement of supplies encourage compliance by remove barriers to proper procedures. Regular inventory monitoring prevent shortages that could compromise safety standards.

Create a culture of food safety awareness encourage voluntary compliance beyond minimum requirements. Recognition programs, team competitions, and peer accountability systems reinforce positive behaviors. Leadership commitment and consistent enforcement demonstrate organizational priorities and expectations.

MORE FROM jobzesty.com